Technical principle and application of die cutting machine

The working principle of the die-cutting machine is to use steel knives, hardware molds, steel wires (or stencils carved from steel plates) to apply a certain pressure through the embossing plate to cut the printed products or cardboard into a certain shape.

How many parts does die-cutting technology include?

1. Die cutting

Die-cut entire prints into individual graphic products.

2. Indentation

Use steel wire to punch marks or leave curved grooves in the print.

3. Hot stamping

Using two templates of Yin and Yang, by heating the mold to a certain temperature, the pattern or font with three-dimensional effect can be hot-stamped on the surface of the printed product.

4. fit

If one substrate is bonded to another substrate.

5. For waste disposal

Exclude the rest except genuine products.

What is the working principle of die-cutting and creasing technology?

Die-cutting and indentation technology is a comprehensive term for two processing technologies, model-based indentation and template-based die-cutting. The principle is to apply pressure in the shaped mold to compress and deform the printing carrier paper. Or break and separate.

The main parts of die-cutting and creasing equipment (referred to as die-cutting machine) are die-cutting plate table and pressing-cutting mechanism. The processed sheet is between the two, and the technical processing of pressure die-cutting is completed.

What are the three basic types of die cutting machines?

There are different types of die-cut creasing boards and corresponding press-cutting mechanisms, so that the die-cutting machine is divided into three basic types: flat type, round flat type and round flat type.

Due to the different directions and positions of the printing plate and the platen, the flat die cutting machine is divided into two types: vertical and horizontal.

What types of die cutting machines are there?

1. Flat die cutting machine

The shape of the plate table and press-cutting mechanism of the die-cutting machine is flat, and when the plate table and the platen are in a vertical position, it is a vertical flat die-cutting machine.

What is the difference between vertical and horizontal flat die cutting machines?

(1) Vertical flat molding press

The structure is simple, the maintenance is convenient, and it is easy to master its operation and replace the die-cut creasing plate, but the labor intensity is high and the production efficiency is low. The number of times of doing work per minute is more than 20-30 times. Often used in small batch production.

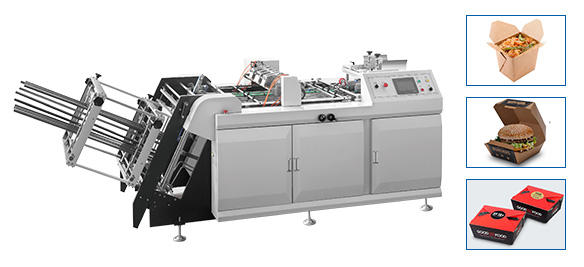

(2) Horizontal die cutting machine

The plate table and platen working surface of the horizontal die-cutting machine are both in a horizontal position, and the plate below is driven by the mechanism to press upwards onto the plate table for die-cutting and indentation.

Due to the small stroke of the platen of the horizontal die-cutting machine, it is difficult to manually put in or take out the cardboard, so it usually has an automatic paper feeding system.

Its overall structure is similar to that of a sheet-fed offset press. The whole machine is made of cardboard automatically. It is composed of input system, die-cutting part, cardboard output part, electrical control, mechanical transmission and other parts, and some are equipped with automatic cleaning device.

The horizontal die-cutting machine is safe and reliable, with high automation and production efficiency. It is an advanced model of flat die cutting machine.

According to the different motion trajectories of the pressure plate, it can be divided into two categories:

When the die-cutting machine is working, the platen is driven onto the printing plate, pressing against the printing plate table.

1. The pressing plate swings around the fixed hinge. Therefore, at the moment of forming, the working surface of the pressing plate has a certain inclination angle with the template surface, so that the die-cutting plate cuts into the lower part of the cardboard earlier, which easily causes excessive pressure on the lower part of the steel mesh. The phenomenon that the upper part is not completely cut through. In addition, the component of the die-cutting pressure will also cause the lateral displacement of the cardboard.

2. When the die-cutting machine with a pressure plate movement mechanism is working, the pressure plate is driven by the connecting rod, first swings on the plane guide rail of the machine base with the cylindrical roller as the fulcrum, and the inclination of the pressure plate on the working surface changes to a molded plate. In the parallel position, press the die-cutting plate in parallel translation.

2. Round Flat Die Cutting Machine

What is the working principle of the circular flat die cutting machine?

The rotary flat die-cutting machine is mainly composed of a reciprocating flat worktable and a rotating cylindrical pressure roller.

1. During the working stroke, the plate table moves forward to die-cut and indent the cardboard

2. When returning to the stroke, the plate table returns, and the working surface of the pressure roller does not touch the die-cut plate.

3. According to the rotation of the pressure roller in a working cycle, this type of die-cutting machine can be divided into several types such as stop-rotation, one-rotation, and two-rotation.

3. Rotary die cutting machine

What is the working principle of the rotary die cutting machine?

The printing plate table and the working parts of the press-cutting mechanism of the rotary die-cutting machine are all cylindrical.

When working, the paper feeding roller sends the cardboard between the stencil cylinder and the pressure roller, and the two are clamped. The die-cutting cylinder rotates one revolution, and the die-cutting cylinder rotates one revolution, which is a working cycle.

The die-cutting methods of the rotary die-cutting machine are generally divided into two types: die-cutting method and soft-cutting method:

(1) Hard cutting method

When die-cutting, the knife is in hard contact with the surface of the pressure roller, so the die-cutting knife is more likely to wear.

(2) Soft cut method

A layer of engineering plastics is covered on the surface of the pressure roller. When die-cutting, the cutter can have a certain amount of cutting, which can protect the cutter and ensure the complete cutting, but the plastic layer needs to be replaced regularly.

Because the cylinder rotates continuously when the rotary die-cutting machine is working, its production efficiency is the highest among all kinds of die-cutting machines. However, the die-cut board must be bent into a curved surface, which is cumbersome and expensive, and the technology is difficult. Circular die cutters are often used in high-volume production.

What is the production process of die-cutting machinery and printing machinery?

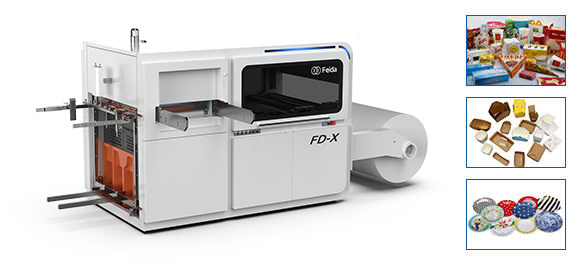

At present, the most advanced die-cutting equipment is developing towards the fully automatic direction of printing and die-cutting.

(1) Feeding part

The cardboard is sent to the printing section intermittently, which can be adjusted conveniently and accurately according to different material shapes, sizes, types, etc.

(2) Printing part

It consists of 4-8-color printing units, and can be adjusted according to different materials. Gravure printing, offset printing, flexo printing and other methods can be used. This part features more advanced printing and is equipped with its own automatic drying system.

(3) Die-cut part

The die-cutting part can be a flat die-cutting machine or a circular die-cutting machine, all of which are equipped with a waste discharge device, which can automatically remove the corner waste generated after die-cutting.

(4) Conveying part

After the die-cutting process is completed, the products are collected, sorted and sent out to ensure that the printing part and die-cutting part of the feeding part can smoothly achieve high-speed continuous operation.

With the improvement of the technical level in recent years, the price of circular die-cutting equipment has been significantly reduced, and it currently has a wide range of user groups in China.

4. Roll Die Cutting Machine

Roll die cutting machine are available in rotary and flat press types.

Flatbed web die-cutting machine is a machine that performs die-cutting and creasing through web feeding, and there are two modes of external connection and on-line.

(1) Offline processing method

Use the printing machine to print the cardboard roll, and then put the roll paper rewound on the roll machine on the paper feed frame of the die-cutting machine for processing. Die-cutting, creasing processing.

The feature of the offline processing method is that the printing machine and the die-cutting and creasing machine are not connected, and there is no restriction on each other. The printing machine can use multiple die-cutting machines to cooperate with the printing machine to adjust the printing, or increase the start-up time of the die-cutting and creasing machine

(2) Online processing method

Connect the die-cutting machine with the printing machine to form an intermodal machine. Starting from the roll cardboard, it is produced by printing, die-cutting and creasing processes.

This method can reduce the number of operators. However, the speed of the general printing machine is higher, and the speed of the die-cutting and creasing machine is lower. The two speeds cannot match. The speed of the printing press can only be reduced. It is impossible to increase the speed of die cutting and creasing machines. Productivity suffers.

5. Online Die Cutting Machine

The so-called online die-cutting mainly refers to online flat die-cutting and online circular die-cutting.

Inline die-cutting has advantages that sheet-fed die-cutting machines cannot match. Some experts predict that it will become the mainstream of the die-cutting equipment market in the next few years.

What is the application field of online die cutting?

At present, it is widely used in the post-press processing of medium and long version packaging products.

What are the characteristics of online die-cutting?

Fast speed and high precision can greatly improve production efficiency, shorten production cycle and reduce production cost.

What are the advantages of online flat die cutting?

The maximum speed of online flat die-cutting can reach more than 20,000 times per hour, which is much higher than that of sheet die-cutting. Since the die-cutting plate used is the same as that used for single-sheet flat die-cutting, the manufacturing process is simple and the cost is low.

What are the advantages of online rotary die cutting?

Online round pressing and round measuring and cutting are mainly used for single-variety and large-volume post-press online. Its main feature is to carry out a series of operations such as bronzing, bronzing, die-cutting, and waste stripping on the printed roll paperboard, so that the printed board can be processed into the final product at one time.

Online rotary die-cutting avoids a series of quality problems such as surface contamination caused by multiple passes of post-press processing, inaccurate positioning of hot stamping, and high reject rate. At the same time, it reduces equipment investment and floor space, saves a lot of operators and shortens the production cycle.

Online Flat Press Die Cutting vs Online Rotary Press Die Cutting

Although online circular die-cutting has some advantages that online flat-bed die-cutting does not have, the cost of die-cutting tools is high and the production of die-cutting plates is complicated.

In addition, online circular die-cutting avoids a series of quality problems caused by multi-pass post-processing, such as surface contamination, inaccurate positioning of hot stamping, and high reject rate. At the same time, equipment investment and floor area are reduced, a large number of operators are saved, and the production cycle is shortened. Therefore, it is used more and more.

Español

Español Français

Français China

China