Fully automatic die-cutting machine: precise positioning and efficient production

In modern manufacturing, the Roll Die Cutting Machine is a core production tool for industries such as labeling, packaging, and printing. Its performance and application scope directly impact production efficiency and product quality. The fully automatic roll-to-roll flatbed die cutting machine and the Roll Die Cutting Machine inline Flexo Printer, as two flagship products, are providing efficient and reliable solutions for customers in different niche markets with their unique technological advantages and precise market positioning.

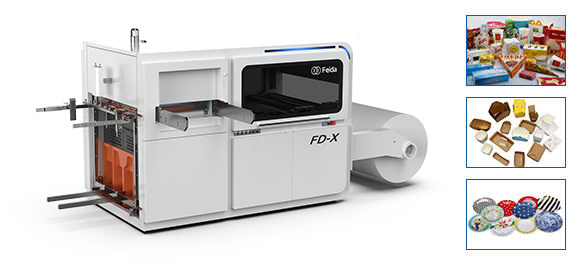

I.Fully Automatic Roll-to-Roll Flatbed Die Cutting Machine: Perfect Combination of High Precision and Flexibility

Target Niche Markets

1. Printing Industry: automatic roll-to-roll die-cutting machine adopts internationally advanced technology and has the characteristics of high stability, high safety performance, and high finished product precision. It is widely used in paper packaging fields such as paper boxes.

2. Packaging Industry

In the packaging field, especially for small-batch, customized box production, the flatbed die cutting machine can quickly switch molds to adapt to different shapes and sizes, helping enterprises achieve efficient and flexible production.

3. Film and Composite Material Processing

For thin materials such as films and adhesives, the flatbed die cutting machine provides stable die-cutting pressure and high-precision cutting, avoiding material deformation or damage. It is widely used in high-end fields such as electronics and medical industries.

Core Advantages

High-Precision Die Cutting: Flatbed die-cutting technology ensures every cut is accurate.

High Flexibility: Supports quick mold changes, suitable for multi-variety, small-batch production.

Easy Operation: Fully automated design reduces manual intervention and lowers operational difficulty.

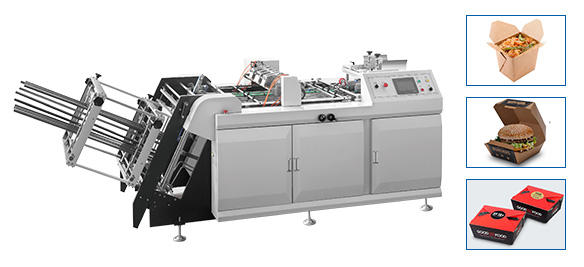

II.Roll Die Cutting Machine Inline Flexo Printer: High-Speed Production and Multi-Functional Integration

Target Niche Markets

1. Adhesive Label Industry

The Roll Die Cutting Machine inline Flexo Printer combines flexographic printing and die-cutting functions, enabling integrated printing and die-cutting in adhesive label production, significantly improving production efficiency, especially for large-volume orders.

2. Flexible Packaging Industry

In the food, daily chemical, and other flexible packaging fields, the flexo die cutting machine can efficiently process materials such as plastic films and aluminum foils, meeting the needs of high-speed, continuous production.

3. Paper Product Processing Industry

For die-cutting and creasing of paper products such as paper cups and paper bags, the flexo die cutting machine provides stable performance and high output, helping enterprises reduce production costs.

III.Core Advantages

High-Speed Production: Rotary die-cutting technology supports continuous high-speed production, suitable for large-volume orders.

Multi-Functional Integration: Can simultaneously complete printing, die-cutting, creasing, and other processes, reducing equipment investment and production steps.

Strong Adaptability: Capable of processing various materials, including paper, films, and composite materials.

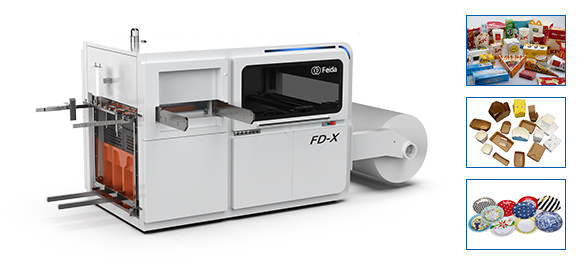

IV.Precise Positioning to Meet Diverse Needs

The fully automatic roll-to-roll flatbed die cutting machine and the Roll Die Cutting Machine inline Flexo Printer target different niche markets to meet customers' diverse production needs:

- The roll die cutting machine is more suitable for high-precision, small-batch, and customized production scenarios, such as high-end labels and packaging boxes.

- The flexo die cutting machine focuses on high-speed, large-volume production, especially for adhesive labels and flexible packaging industries.

Through precise market positioning and continuous technological innovation, these two machines are creating greater value for customers in industries such as labeling, packaging, and printing, helping enterprises achieve efficient and intelligent production upgrades.

Conclusion

Whether pursuing high precision or high efficiency, the fully Feida automatic roll-to-roll flatbed die cutting machine and the Roll Die Cutting Machine inline Flexo Printer can provide tailored solutions for customers. In the future, as market demands continue to evolve, these two machines will continue to drive innovation, empower more industries, and promote the development of intelligent and efficient manufacturing.

Español

Español Français

Français China

China