What are the Limitations of Roll Die Cutting Machines?

When considering roll die cutting machines as a manufacturing solution, we must be aware of some of their limitations.

The following are several limitations of roll die cutting machines:

1. Limited flexibility

Flexibility is limited, and you can't easily switch shapes or make on-the-fly adjustments.

2. Customized molds are costly

Custom molds are costly, especially for complex shapes or designs.

Tooling cost can become an important factor, especially for small-scale or custom production runs.

3. Material limitations

Limited scope of application, mainly suitable for cutting thin and flexible materials

Roll die-cutting machines may not be suitable for thick or rigid materials that require greater force or specialized cutting techniques.

4. Waste generation

Roll die cutters produce waste in the form of leftover material around the cut shape.

This waste material may not always be reusable or recyclable, resulting in increased production costs and increased environmental impact.

5. Lack of accuracy in some applications

While roll die-cutting machines provide reasonable accuracy for many applications, they may not provide the level of accuracy required for highly complex or critical parts.

Certain applications may require more precise cutting methods, such as laser cutting or waterjet cutting.

Here are a few advantages of roll die cutting machines:

1. Efficient production speed

The roll die-cutting machine can automatically complete the cutting work at high speed and improve production efficiency.

They are ideal for large-scale and high-volume production.

2. Low cost and rapid production preparation

Production using a web die-cutting machine is often more economical and faster than other cutting methods.

Once the appropriate mold is configured, preparation time is short and production can begin quickly.

3. Simple operation and easy to learn

Roll die-cutting machines typically have user-friendly interfaces and operating systems that allow operators to get up and running quickly.

4.Customizability

Although roll die-cutting machines lack flexibility to some extent, molds can be customized according to needs to meet the diverse needs of different products.

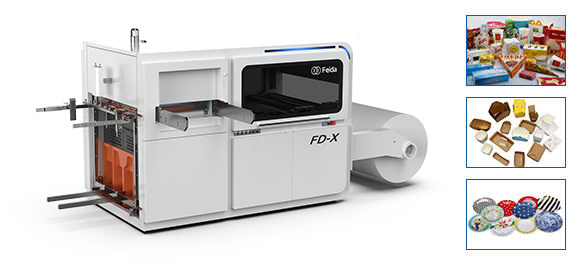

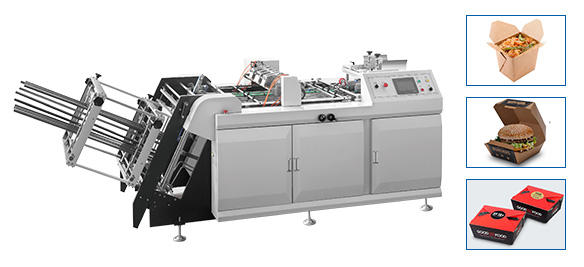

5. Versatility

Roll die cutting machines can be used to cut a variety of materials such as paper, cardboard, foam, rubber, and plastic. They have a wide range of applications in many industries.

6. Reliability and stability

Roll die-cutting machines are usually made of high-quality materials and manufactured with precise processes, so they have good reliability and stability and can continue to produce for a long time.

Summarize

It is important to consider the above limitations as well as the advantages when determining whether a web die-cutting machine is the right manufacturing solution for a specific product or industry.

Español

Español Français

Français China

China