Introduction:

FDC series automatic roll punching machine based on international advanced technology, it’s widely used in paper cup fan products. It adopts micro-computer, human-computer control interface, servo positioning, alternating current frequency converter, photoelectric correcting deviation system, centralized oil lubrication.

The equipment is suitable for paper thickness of 150-350 gsm roll paper for rapid and precise punching, collecting and stripping at the same time, can be applied to paper cups, paper bowl, paper plate etc.

|

Model |

FDC850 |

FDC920 |

FDC1000 |

FDC1200 |

|

Max Paper Width |

850mm |

920 |

1000 |

1200 |

|

Cutting Precision |

±0.20mm |

|||

|

Paper Gram Weight |

150-400g/㎡ |

|||

|

Production Capacity |

280-380times/min |

280-380times/min |

280-330times/min |

260-300times/min |

|

Air Pressure Requirement |

0.6Mpa |

|||

|

Air Pressure Consumption |

0.25m³/min |

|||

|

Weight |

3.5T |

4T |

4.5T |

5T |

|

Max Roller Diameter |

1500mm |

|||

|

Total Power |

10KW |

10KW |

10KW |

12KW |

Main Structure

1. It adopts micro-computer, human-computer control interface, direct connection servo positioning which make higher accurancy, and we make the wallboard, base much stronger than others, it guarantees that when the machine runs up to 380 strokes/min without any shaking.

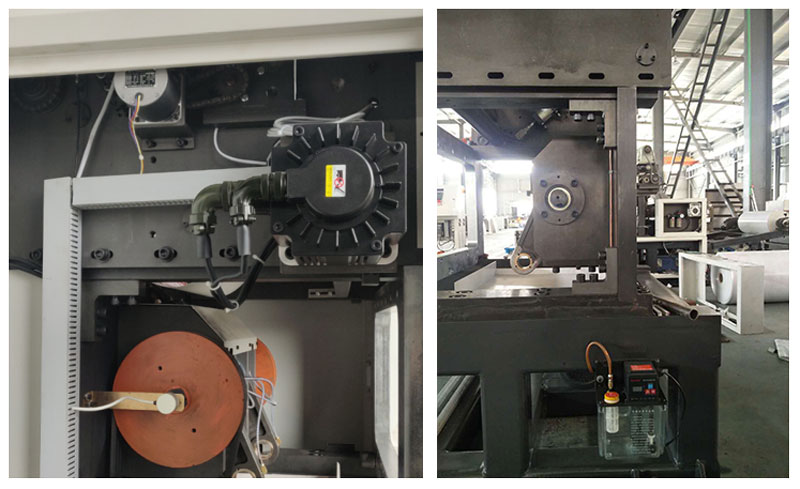

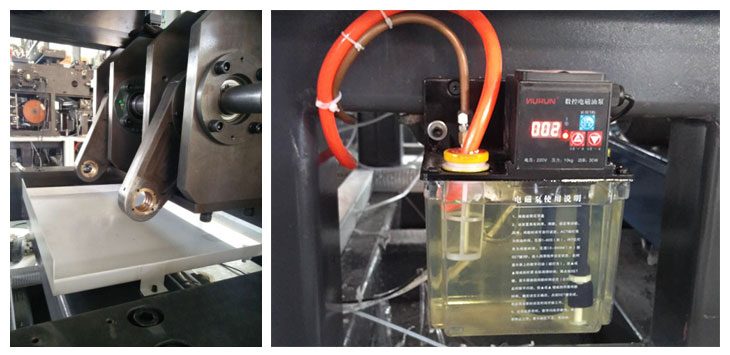

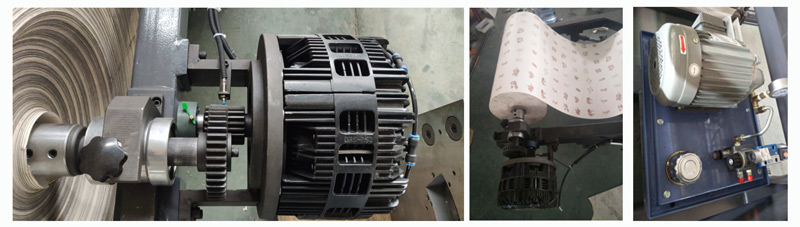

2.Lubrication System: Adopts forced lubrication system to ensure main driving oil supply regularly and reduce friction and prolong the machine life, you could set it to lubricate 10 secondes every 6 minutes.

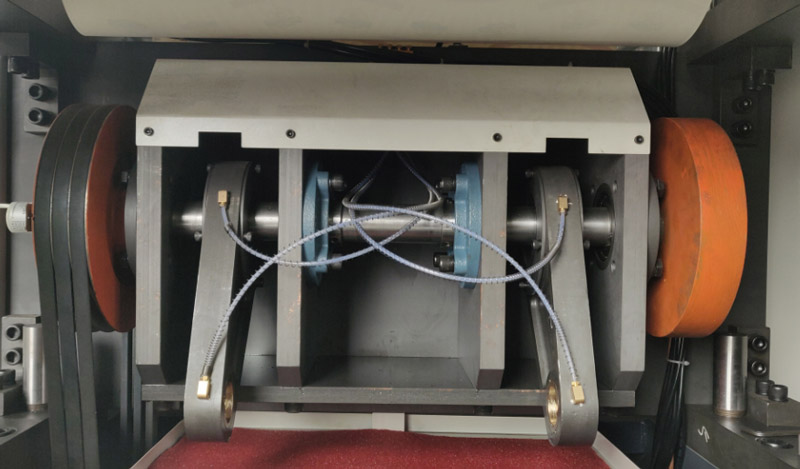

3. The die-cutting force is provided by a 5.5KW inverter motor. It is not only power-saving, but also can realize the stepless speed adjustment, especially when coordinate with the extra large flywheel, which make the die-cutting force strong and steady, and the electricity can be further reduced.

We adopt two swing arm cams which are much easier to adjust and opearte when you change the punching mould, and it has higher stable pressure and higer performance.

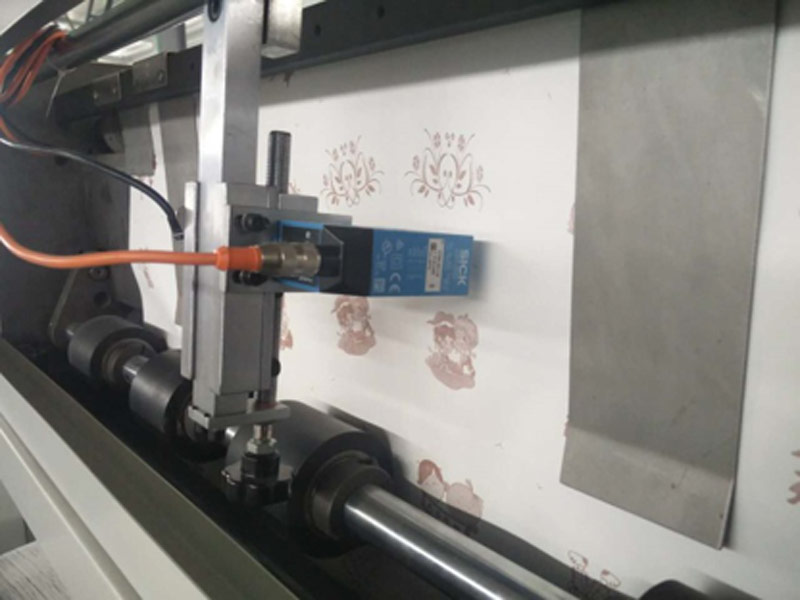

4. The coordination between stepping motor and photoelectric eye which can identify colors assures the perfectly fit of the die-cutting position and figures.

5. Electrical Cabinet: Frequency converter controls the main motor, with features of low energy and high efficiency. PLC and HMI: screen display the running data and status, all of the parameter can be set through the screen. Electrical Control System: adopts micro computer control, encoder angle detect and control, photoelectric chase and detect, achieving from paper feeding, convey, die punching and delivering process automatic control and detect. Automatic Tension Control can control the paper tension automatically.

6. Feeding Unit: Adopts chain type pneumatic roller unwind, tension controls unwind speed, and that’s hydraulic, it could support at 1.5T paper. Max roll paper diameter 1.5m.

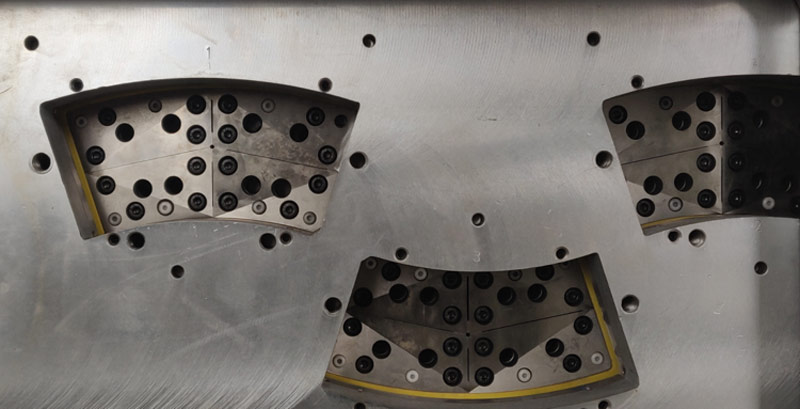

7. Die cutting mold: we adopt swiss material that could be used for at least 400 million strokes, and if the mold can’t cut well, you could sharpen the blade by flat grinding machine, it could be sharpen 4-5times.

Each punching mould in one cavity is divided into 4 pieces which can be adjusted easily.

Due to the epidemic situation, most exhibitions at home and abroad have been cancelled, and we ...

Carton erecting machine performs a range of functions, including folding, gluing, and shaping t...

Roll die-cutting machines may not be suitable for thick or rigid materials that require greater...

There are several types of web die-cutting machines available, each designed for specific appli...

Roll die cutting machines, also known as rotary die-cutting machines, are designed to cut mater...

A high-quality paper box forming machine can efficiently handle various types of paper, while h...

Roll die cutting machines provide high precision and accurate cutting. Using a sharp blade or c...

In the printing industry, precision and reliability are crucial. This is why many companies rel...

GET A QUOTE