Automatic Paper Box Forming Machine vs. Automatic Lunch Box Making Machine: Key Differences

In the packaging industry, automated machines play a crucial role in manufacturing different types of containers, including paper boxes and lunch boxes. While both Paper Box Forming Machines and Lunch Box Making Machines are designed for shaping paper-based materials, they serve distinct purposes and operate differently. This article explores their differences in terms of functionality, applications, and production processes.

I. Purpose and Applications

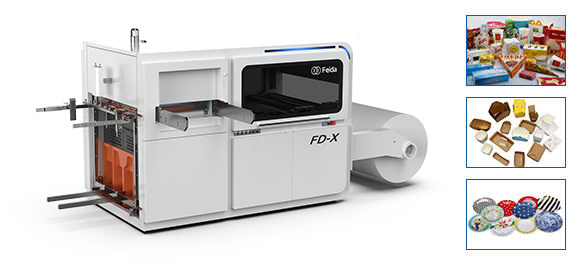

Paper Box Forming Machine (Paper Box Making Machine)

Primarily used to produce folding cartons, gift boxes, cosmetic packaging, and retail boxes.

Suitable for rigid or semi-rigid paperboard materials.

Commonly used in industries like e-commerce, pharmaceuticals, food packaging, and luxury goods.

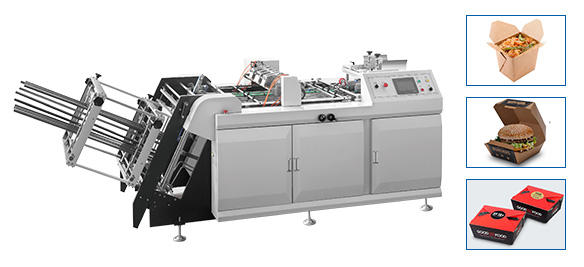

Lunch Box Making Machine

Specifically designed to manufacture disposable food containers, such as takeaway boxes, compartment trays, and biodegradable lunch boxes.

Works with food-grade paperboard or molded pulp to ensure safety and durability.

Widely used in restaurants, fast-food chains, catering services, and eco-friendly packaging industries.

II. Material and Structural Differences

| Feature | Paper Box Forming Machine | Lunch Box Making Machine |

| Material | Cardboard, Kraft paper, corrugated board | Food-grade paper, molded pulp, PLA-coated paper |

| Structure | Rigid or foldable boxes with glued seams | Press-formed or thermoformed with flanges for sealing |

| Water/Oil Resistance | Optional coatings (not always food-safe) | Often includes PE or PLA coating for grease resistance |

III. Production Process

Paper Box Forming Machine

1.Feeding – Sheets of paperboard are fed into the machine.

2.Cutting & Creasing – Die-cutting and creasing create the box template.

3. Folding & Gluing – The machine folds and secures edges with adhesive.

4. Output – Finished boxes are stacked for packaging.

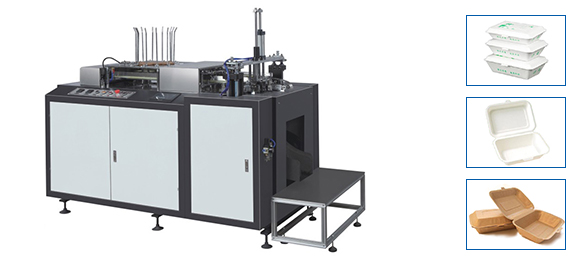

Lunch Box Making Machine

1. Material Heating (for thermoforming) – Food-grade paper is heated for molding.

2. Pressing & Shaping – Hydraulic or mechanical presses form the container shape.

3. Edge Sealing – Flanges are pressed for secure closure.

4. Cooling & Ejection – Finished lunch boxes are cooled and collected.

IV. Automation and Customization

Paper Box Machines often allow high customization in printing, embossing, and box styles.

Lunch Box Machines focus on high-speed production with standardized sizes for food safety compliance.

Conclusion

While both Paper Box Making Machine and Lunch Box Making Machine transform paper materials into functional packaging, their design, materials, and end uses differ significantly. Choosing the right machine depends on whether the priority is retail-ready packaging or food-safe disposable containers.

For businesses in food service, a Lunch Box Making Machine is essential, while brands needing premium packaging should opt for a Paper Box Forming Machine. Understanding these differences ensures optimal efficiency and product quality in packaging production.

Español

Español Français

Français China

China