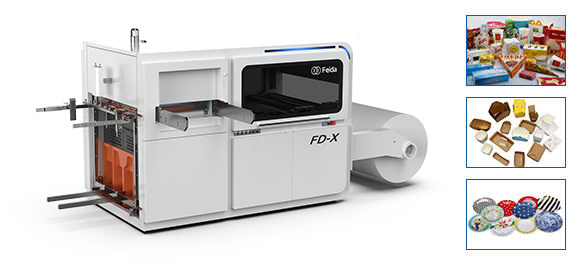

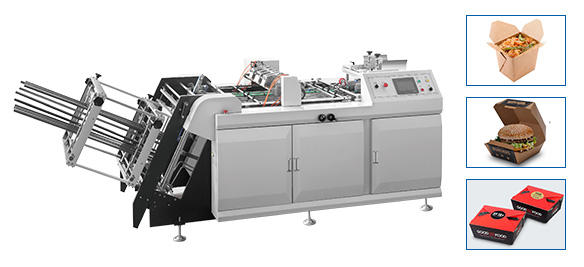

What Process Does the Roll Die Cutting Machine Use?

Roll die-cutting machines use a rotary process to cut material from a continuous roll.

Material is fed from a roll and the machine uses a rotating cylindrical die to cut the material into the desired shape or pattern.

Here's a step-by-step guide to the process:

1. Feeding

The material is fed from the roll into the machine through a feeding device. The feeding device ensures consistent speed and tension.

2. Positioning

Guides and sensors are used to position the material in the machine. This ensures that the material is properly aligned with the cutting die.

3. Die cutting

The material is cut using a rotating cylindrical die mounted on a rotating press. Molds are custom-made to fit the specific design or pattern required for the product.

4. Waste removal

After the material is cut, use a scrap removal device to remove the scrap. Scrap can be collected and disposed of or recycled.

5. Product stacking

Finished products are neatly stacked on output pallets or conveyor belts.

6. Repeat

This process is repeated continuously as long as there is material in the rollers and molds in the machine.

Summarize

Roll die cutting machines provide a fast and efficient way to produce high volumes of precision cut products.

By feeding continuous rolls of material into the machine, the process can be automated to save time and reduce labor costs.

Español

Español Français

Français China

China