Application of Roll Die Cutting Machine

Improve efficiency and apply roll die-cutting machine technology

With the continuous advancement of manufacturing technology, various industries have increasingly higher requirements for production efficiency and quality control. Against this background, roll die-cutting machine technology, as an efficient and precise processing tool, is gradually becoming the first choice for many industries. This article will introduce the applications of web die cutting machines and the many benefits they bring.

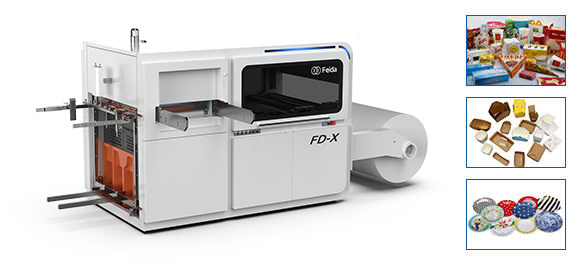

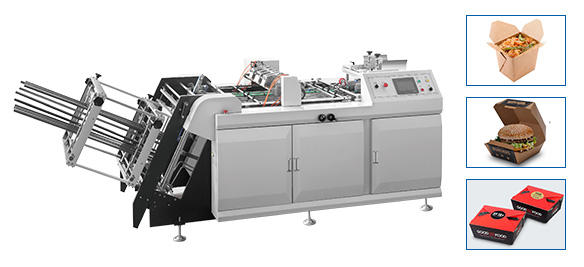

What is a roll die cutting machine?

A roll die-cutting machine is a device used to cut roll materials (such as paper, tape, film, etc.) into specific shapes. It uses advanced automation technology to precisely control cutting size and shape, and is suitable for various materials and complex processing needs.

Application areas

Packaging industry: Roll die-cutting machines are widely used in the packaging industry. It can quickly and accurately cut roll material into various shapes of packaging boxes, labels, etc., improving production efficiency and product quality.

Printing industry: The roll die-cutting machine can be used for post-processing of printed matter, such as cutting book covers, stickers, cards, etc. It can achieve high-speed, high-precision cutting, saving labor and time costs for printing companies.

Pharmaceutical industry: In pharmaceutical packaging, roll die-cutting machines can cut pharmaceutical packaging boxes, instructions and other materials as required to ensure the integrity and safety of the packaging.

Electronics industry: Roll die-cutting machines are also widely used in the manufacturing of electronic products, such as the production and processing of mobile phone screen protectors, battery stickers, etc.

Advantages and Benefits

Improve production efficiency: The roll die-cutting machine adopts automation technology and can achieve continuous and high-speed production and processing, which greatly improves production efficiency and reduces labor costs.

Precise control: Through the advanced control system, the roll die-cutting machine can precisely control the cutting size and shape to ensure product consistency and quality.

Save raw materials: Due to its high cutting accuracy, the roll die-cutting machine can minimize the waste of raw materials and save production costs.

Diversified processing: The roll die-cutting machine can be customized according to customer needs to meet the needs of products of different shapes and sizes, and has strong flexibility and applicability.

Conclusion

With the continuous advancement of industrial technology, roll die-cutting machines, as an efficient and precise processing equipment, will play an increasingly important role in various industries. It can not only improve production efficiency and reduce production costs, but also improve product quality and meet customers' personalized needs. Therefore, investment and application of roll die-cutting machine technology will become one of the important means for enterprises to improve their competitiveness.

Español

Español Français

Français China

China