Flexo Printing Machine: A Printing Giant for Multiple Applications

In today's highly developed industrial era, printing technology is evolving rapidly. Among them, Flexo Printing Machine (Flexo Printing Machine) occupies an important position in the printing industry with its unique advantages and wide range of applications. It can not only achieve high-quality printing results, but also has the characteristics of environmental protection, high efficiency, flexibility, etc., which provides strong support for the development of many industries.

Working Principle and Characteristics of Flexo Printing Machine

* Working Principle

The working principle of Flexo Printing Machine is to transfer ink to the printing plate through anilox rollers, and then the printing plate will transfer ink to the substrate. The printing plate is soft and bendable, which can adapt to the surface of different shapes of substrates and achieve all-round printing.

* Characteristics

(1) Environmental protection: Flexographic printing presses usually use water-based inks or UV inks, which are more environmentally friendly than traditional inks, reducing pollution of the environment.

(2) High efficiency: the printing speed of the flexographic printing machine is faster, to meet the needs of mass production. At the same time, its higher degree of automation, reducing manual operation and improving production efficiency.

(3) Flexibility: the flexibility of the printing plate makes the flexographic printing machine can adapt to different thicknesses and materials of the substrate, including paper, plastic, film, metal and so on. In addition, multi-color printing and spot-colour printing can be carried out to meet a variety of complex design requirements.

(4) Cost advantage: Compared with other printing methods, the equipment investment and running cost of flexographic printing machine is relatively low. At the same time, due to its stable printing quality, it reduces the scrap rate and further reduces the production cost.

The application areas of Flexo Printing Machine

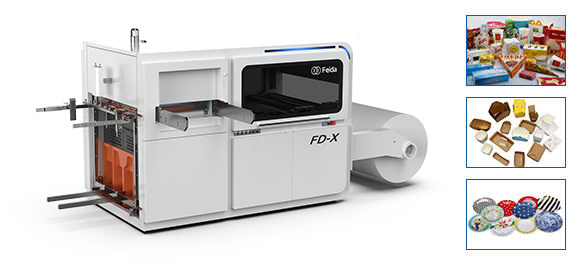

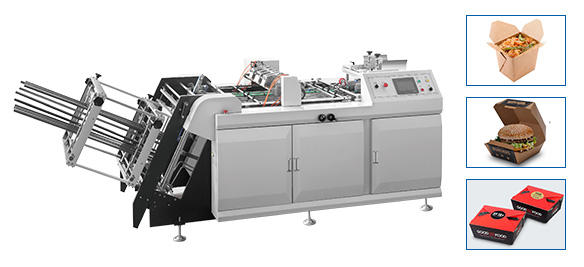

1. Food packaging field

Food packaging is one of the important application areas of Flexo Printing Machine. In the supermarket shelves, we can see a variety of beautiful food packaging, such as biscuit bags, candy boxes, beverage bottle labels, etc., many of which are printed by the flexographic printing machine. Food packaging on the printing quality and safety requirements are extremely high, flexographic printing machine using environmentally friendly inks in line with the safety standards of food packaging, can ensure the quality and safety of food. At the same time, its high-quality printing effect can attract the attention of consumers and improve the market competitiveness of the product.

2. Pharmaceutical packaging field

Pharmaceutical packaging has very strict requirements for printing precision and accuracy, because the accurate communication of pharmaceutical information is related to the health and safety of patients. Flexographic printing presses are able to accurately print drug descriptions, bar codes, anti-counterfeiting logos and other content to ensure the traceability and safety of drugs. In addition, pharmaceutical packaging usually requires the use of special materials, such as moisture-proof, light-proof and oxidation-proof materials, etc. Flexographic printing presses are able to adapt to the printing needs of these materials, providing reliable solutions for pharmaceutical packaging.

3. Daily necessities packaging field

Packaging for daily necessities covers a wide range of products such as shampoos, shower gels, cosmetics and so on. Flexographic printing presses can give the packaging of these products a beautiful appearance and attract consumers' desire to buy. It is capable of printing delicate patterns and rich colours, as well as adapting to packaging containers of different shapes and materials, meeting the diverse needs of the daily necessities packaging industry.

4. Label printing field

Labels play an important role in the circulation of goods, which can not only provide information on goods, but also play the role of anti-counterfeiting, promotion and so on. Flexographic printing machine has a unique advantage in label printing, it can print small size, high resolution labels, but also to adapt to a variety of special shapes and materials of the label material. Whether it is self-adhesive labels, shrink film labels or in-mold labels, Flexo Printing Machine can easily deal with.

The future development trend of Flexo Printing Machine

Intelligent development

With the continuous progress of science and technology, the flexo printing machine will be towards the direction of intelligent development. The future of the flexo printing machine will have a higher degree of automation, can achieve automatic loading, automatic printing, automatic detection and other functions. At the same time, it can also be achieved through the Internet technology remote monitoring and troubleshooting to improve the operational efficiency and stability of the equipment.

Green environmental protection development

Environmental protection is the theme of future industrial development, flexographic printing presses will also continue to develop in the direction of green environmental protection. On the one hand, it will continue to promote the use of environmentally friendly inks to reduce environmental pollution; on the other hand, it will optimise the structure of equipment and printing process to reduce energy consumption and waste emissions to achieve sustainable development.

Multifunctional development

In order to meet the needs of different customers, flexographic printing machine will continue to expand its functions. The future flexographic printing machine will not only be able to print, but also can achieve varnishing, laminating, die-cutting and other processes, providing customers with one-stop printing solutions.

Conclusion

Flexo Printing Machine, as an advanced printing equipment, plays an important role in many fields such as food packaging, pharmaceutical packaging, daily necessities packaging, label printing and so on with its unique working principle and characteristics. With the continuous progress of science and technology and the constant change of market demand, flexo printing machine will continue to develop and innovate towards the direction of intelligent, green and multi-functional. I believe that in the future, flexographic printing machine will bring more beautiful printing products for our life, and make greater contribution to the development of various industries.

Español

Español Français

Français China

China