What Machine is Used for Die Cutting?

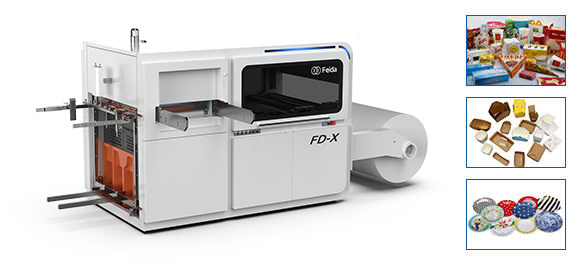

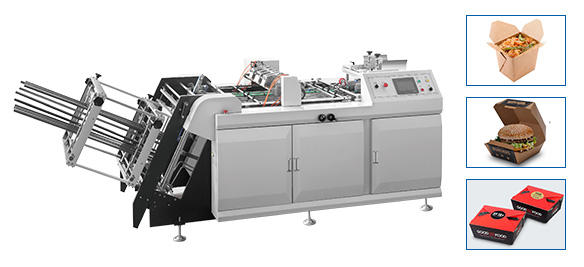

The roll die cutting machine can be used for die cutting. The roll die cutting machine is a versatile and efficient tool for die cutting a variety of materials.

What does die cutting mean?

Die cutting is a process that involves cutting or shaping materials into a specific pattern or design using specialized tools called dies.

Web die-cutting machines are specifically designed to process continuous rolls or sheets, making them suitable for high-volume production and large-scale projects.

Web die cutting machines operate with a combination of precision, pressure and speed for accurate and consistent cuts.

Here are some key aspects of roll die cutting machines:

1. Structure and components

Roll die cutting machines usually consist of a sturdy frame that houses several important components.

Web die cutting machines are designed to provide stability, durability and ease of operation.

(1) Feeding system

(2) Cutting mechanism

(3) Control panel

(4) Waste removal system

2. Feeding system

The roll die-cutting machine is equipped with a feeding system that can feed materials continuously.

Roll die-cutting machines can handle various types of materials, such as rolls or sheets of paper, cardboard, fabrics, adhesive films or plastics.

The feed system ensures precise control and alignment of the material during cutting.

3. Cutting mechanism

The cutting mechanism of a roll die cutting machine consists of a rotating roller or cylinder with a die attached to its surface.

As the material passes through the machine, it comes into contact with the rotating die, which presses against the material with great force.

The sharp blade or cutting edge on the mold penetrates the material, resulting in a clean, accurate cut.

4. Control Panel

Roll die-cutting machines are equipped with control panels that allow the operator to adjust various parameters to optimize the cutting process.

These parameters can include cutting speed, pressure, depth, and other settings based on the type and thickness of the material being cut.

Control panels offer flexibility and customization to meet specific requirements.

5. Waste removal system

During the die-cutting process, scrap or excess material is produced.

Roll die-cutting machines are equipped with scrap removal systems, such as scraping mechanisms or vacuum systems, to remove scrap and separate it from the finished product.

This ensures efficient operation and minimizes downtime for waste disposal.

What are the applications of roll die cutting machines?

Roll die-cutting machines are widely used in packaging, label manufacturing, printing, automotive, electronics and other industries.

Roll die cutting machines are used to produce a variety of products such as labels, stickers, decals, gaskets, foam inserts, patches, folding cartons, and many other custom shapes and designs.

What are the advantages of roll die cutting machines?

1. High quality and guaranteed consistency

Roll die-cutting machines can achieve high-speed, high-precision cutting, ensuring consistent production quality and efficiency.

2. Versatility

Roll die cutting machines can handle a variety of materials and thicknesses, providing versatility for a variety of applications.

3. Improve productivity

Roll die-cutting machines can increase productivity because they can handle continuous rolls or sheets.

Summarize

Roll die cutting machines are important tools for die-cutting operations, especially when processing continuous rolls or sheets.

Español

Español Français

Français China

China