Maximize Efficiency with Full Stripping Roll Die Cutting Machine

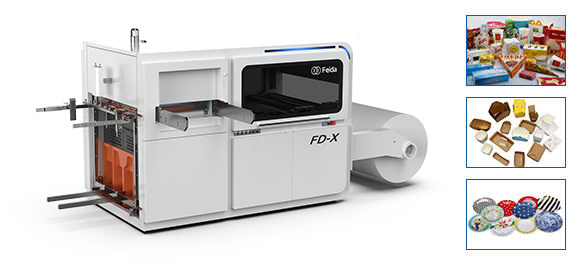

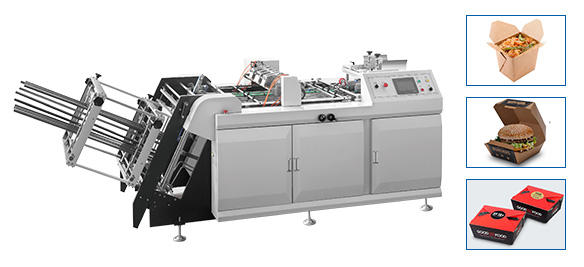

In the modern paper packaging industry, the Full Stripping Roll Die Cutting Machine has become an important equipment to improve production efficiency and product quality. This machine integrates multiple processes such as die cutting, creasing, stripping and collection, and is widely used in the production of various paper products, such as paper cups, paper boxes, food packaging, medical packaging, etc.

Technical Features and Advantages

Die Cutting Accuracy

Die cutting is the backbone of many packaging solutions, from boxes to complex shapes used in product displays. The Full Stripping Roll Die Cutting Machine improves accuracy by integrating advanced servo control systems. This technology ensures precise positioning and consistent cutting pressure, which is essential for maintaining high-quality output during large-scale production.

Enhanced Stripping Capability

In addition to basic die cutting, the machine's stripping function is where it really shines. The Full Stripping Roll Die Cutting Machine automatically removes waste from die-cut pieces. This traditionally labor-intensive process has now been streamlined to minimize downtime and increase production. Whether processing simple shapes or complex designs, the machine can efficiently handle a variety of materials.

Versatility for a Variety of Materials

From paperboard to corrugated board and even flexible materials like foil and laminate, the Full Peel Web Die Cutter demonstrates exceptional versatility. It can accommodate different thicknesses and strengths to meet the diverse needs of the packaging industry. This flexibility not only increases production efficiency, but also expands creative possibilities for designers and manufacturers.

Speed and Efficiency

Time is money in manufacturing, and this machine excels in both areas. With high-speed capabilities and quick setup times, it significantly reduces production cycle times compared to traditional methods. Operators can achieve faster turnaround times without compromising quality, meeting the demands of today's dynamic market landscape.

Cost-Effectiveness and Sustainability

In addition to operational efficiency, the Full Peel Web Die Cutter also contributes to cost-effectiveness and sustainability. By minimizing material waste through precise cutting and peeling, it supports environmentally responsible practices. In addition, its durability and longevity can bring long-term cost savings to businesses that invest in modern production technology.

Conclusion

The Full Peel Web Die Cutter represents a key advancement in the packaging and printing industry. It combines precision, speed, versatility, and sustainability, making it an indispensable tool for manufacturers striving to stay ahead of the curve. As consumer demands evolve and competition intensifies, leveraging this cutting-edge technology is not only beneficial, but essential to achieving operational excellence and maintaining a competitive edge in the market.

By leveraging the capabilities of full-peel web die-cutters, manufacturers can raise production standards, meet customer expectations with greater efficiency, and drive innovation in packaging design and functionality.

Español

Español Français

Français China

China