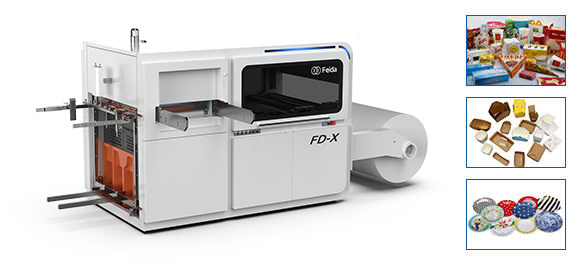

Roll Die Cutting Machine in Rotary Die Cutting

A Roll Die Cutting Machine is a specific type of rotary die cutting machine that uses a roll-to-roll system, where the material is fed from a continuous roll (web) into the cutting station, and then the finished products are rolled up again. The machine is designed to handle continuous production with high-speed cutting, ideal for mass production in various industries like packaging, labeling, and electronics.

How It Relates to Rotary Die Cutting

The Roll Die Cutting Machine operates based on the rotary die cutting process. The key difference is in the material feed system: instead of cutting individual sheets, the machine processes a continuous web of material that is unrolled from a large roll and then rewound after the cutting operation is completed.

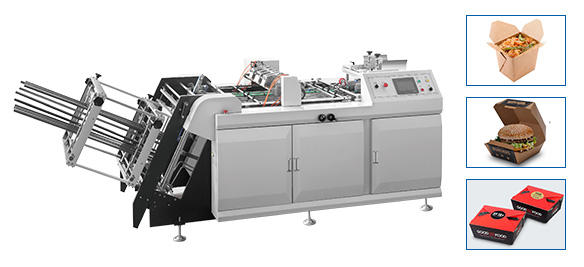

This setup allows for continuous, high-volume production, making it particularly well-suited for applications that require large quantities of identical or similar products, such as:

Labels: Rolls of adhesive labels or stickers

Packaging: Continuous web-based packaging materials like flexible films or boxes

Electronics: Gaskets and seals that require precise and consistent cuts

Advantages of Roll Die Cutting Machines

High Efficiency: The continuous feed from the roll allows for faster cutting speeds and minimal downtime, improving overall production efficiency.

Cost-Effective for High Volumes: Like other rotary die cutting methods, roll die cutting is very cost-effective when used for mass production, reducing material waste and increasing output.

Consistency: The roll-based process maintains uniformity in size and shape, which is essential in high-demand industries like packaging and labels.

Reduced Labor and Material Handling: Since the material is handled in large rolls rather than individual sheets, the need for manual handling is minimized, reducing labor costs and potential for errors.

Conclusion

A Roll Die Cutting Machine integrates seamlessly with the rotary die cutting process, offering the same precision, speed, and versatility, but with the added benefit of continuous material handling. This makes it an excellent choice for industries requiring high-volume, consistent output, such as packaging, labels, and electronics.

Español

Español Français

Français China

China