Is Roll Die Cutting Machine characteristics?

1、First, the basic working principle of Roll Die Cutting Machine

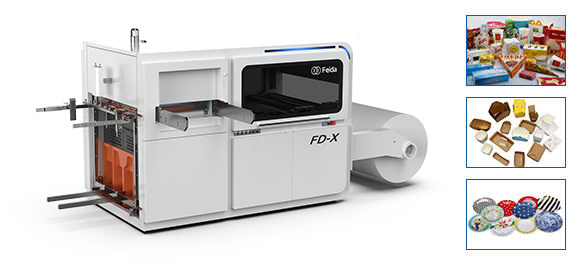

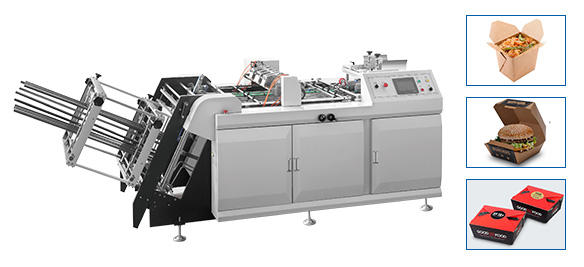

Roll Die Cutting Machine mainly realizes die-cutting action by rotating hob and bottom roller. When the material (such as paper, plastic film, leather, etc.) is transported to the hob and the bottom roller between the hob, the hob on the special blade shape in accordance with the preset pattern to cut the material. The hob rotates continuously under the motor drive, and the material advances at a constant speed, thus continuously completing the die-cutting task, which can efficiently handle long rolls of material and realize mass production.

2、The main components of Roll Die Cutting Machine

The main components include hob assembly, bottom roller, transmission system, feeding system and frame. Hob assembly is the core part, including hob and knife seat, the quality and precision of the hob directly affects the die-cutting effect. The bottom roller is used to support and cooperate with the hob to ensure that the material has a stable support when cutting. The transmission system is responsible for transmitting the power to the hob and the feeding mechanism to ensure the coordinated operation of the components. The feed system precisely controls the speed and position of the material. The machine frame provides a solid support structure for the whole machine.

3、Classification of Roll Die Cutting Machine

According to the function can be divided into ordinary die-cutting machine and multifunctional die-cutting machine, multifunctional die-cutting machine may be both hot stamping, creasing and other functions; according to the size of a small desktop, medium-sized and large-scale industrial and other specifications to adapt to the needs of different scale of production; from the point of view of the application industry, is widely used in the packaging industry, label printing, automotive interior processing, electronic materials processing and other fields, different industries on the hobbing die-cutting machine precision, Different industries have different requirements on the precision, speed and function of the hob die-cutting machine.

4、Fourth, the advantages and disadvantages compared with the flatbed die cutting machine

Advantages, Roll Die Cutting Machine is suitable for continuous production, die cutting speed, high production efficiency, especially for large quantities of long rolls of material processing. It has a higher degree of automation and is more consistent in the material transportation and cutting process. The disadvantage is that the initial equipment investment cost of Roll Die Cutting Machine is relatively high. For small batch, multi-species and large size change orders, its mold replacement and debugging is relatively complex, less flexible than flatbed die cutting machine. And in terms of die-cutting accuracy, for some ultra-fine complex pattern processing, flatbed die-cutting machine may be more advantageous.

Español

Español Français

Français China

China