Your Comprehensive Guide to Die-Cutting Machines

Die-cutting machines play a crucial role in various industries, from small print shops to large-scale manufacturing facilities. They are essential for cutting materials into customized shapes used in packaging, signage, and graphic arts. Beyond cutting, some commercial die-cutting machines can emboss, perforate, crease, form, and laminate materials. This guide will explore different types of die-cutting machines, their applications, and their respective advantages and disadvantages.

Manual vs. Automatic Die-Cutting Machines

Die-cutting machines are broadly classified into manual and automatic types. Manual machines require operators to feed materials manually, which is slow and labor-intensive. In contrast, automatic machines are designed to continuously feed materials, significantly boosting efficiency and productivity.

Flatbed vs. Roll Die Cutting Machines

Industries utilize industrial die-cutting machines for high-volume production needs. For example, the packaging industry employs these machines to create boxes and cartons, while the sign-making sector uses them for cutting vinyl and acrylic for signage and displays. In the graphic arts field, they are crucial for precise cutting in activities like card making and scrapbooking.

There are two main types of industrial die-cutting machines:

Flatbed Die-Cutting Machines

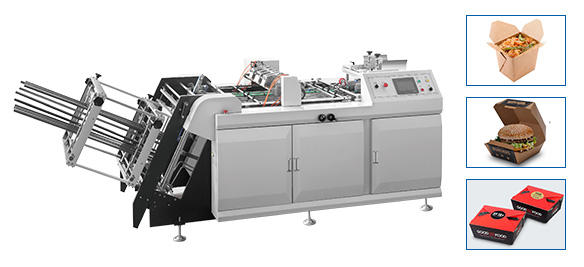

Flatbed die-cutting machines, also known as platen die-cutting machines, are robust and versatile in handling various materials:

Advantages:

1. Capable of handling large materials and a wide range of thicknesses, both in sheets and rolls.

2. Precision cutting of closely grouped shapes, minimizing material wastage.

3. Generally more cost-effective compared to rotary die-cutting machines.

Limitations:

1. Slower operation due to the stop-and-start process, which affects productivity.

2. While accurate, may not match the precision of rotary die-cutting machines.

3. Limited functionality—cannot perform tasks like printing, perforation, or lamination directly.

4. Longer setup time required between jobs.

Roll Die Cutting Machines

Roll die cutting machines are designed specifically to handle materials in roll form:

Advantages:

1. High-speed operation, making them ideal for high-volume production environments.

2. Exceptional precision, suitable for intricate cutting tasks.

3. Versatility in performing tasks such as printing, perforation, and lamination directly.

4. Capable of kiss cutting, leaving the backing paper intact.

Limitations:

1. Higher initial costs due to tooling, setup, and dies, typically suited for larger scale production.

2. Limited width capacity compared to flatbed machines, restricting use for wider materials.

3. Challenges in cutting thicker and denser materials effectively.

4. Requires materials to be in roll form, not suitable for sheet materials without modification.

Choosing the Right Die-Cutting Machine

Selecting between flatbed and roll die cutting machines depends on your specific business requirements. Consider factors such as production volume, material type, precision needs, and budget constraints when making your decision. It's crucial to procure your die-cutting machine from a reputable manufacturer to ensure reliability and quality.

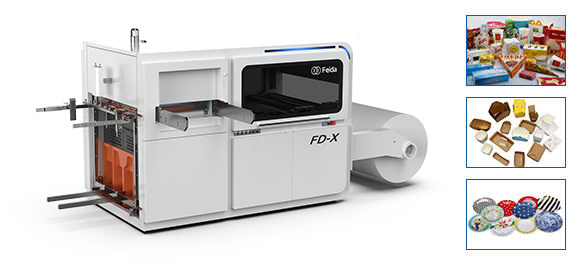

Feida Machinery stands out as a trusted manufacturer offering customizable roll die cutting machines and top-quality automatic platen creasing and cutting machines. Contact us today to learn more about our range of die-cutters and how they can enhance your operations.

Español

Español Français

Français China

China